Black Bird

High Powered Model Rocket (2019)

This project was undertaken during Winter Internship 2019 at Avionics Lab, Space Technology and Rocketry (STAR), Surat, India

Project Mission:

To design and develop a High Powered Model Rocket. This Rocket shall reach a minimum height of 120 meters Propulsively and shall have a Recovery System to land on the ground safely.

A Team comprising 9 interns worked on different aspects of the Rocket, namely 2 interns worked on the Design, 2 interns worked on Avionics, 2 interns worked on Recovery System and 3 interns worked on Propulsion.

My Role:

- Member of Avionics Team, I was responsible for the developing Avionics system onboard the rocket to trigger recovery system and collect data.

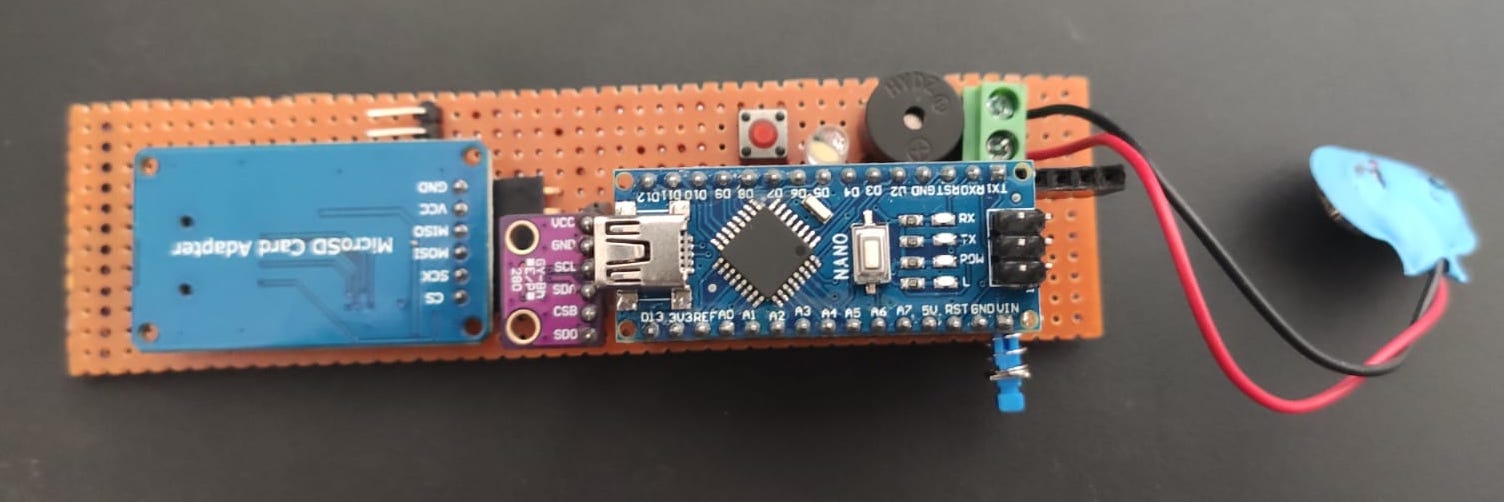

- Designed General Circuit Board (GCB) based on the dimensions of the rocket, the board had a microcontroller, sensors and data storage devices. The build process included the following steps:

- Roughly Planning the Positioning of various components on paper based on their proximity to the Microcontroller.

- Designing the Circuit by Computer-Aid using Eagle software.

- Realising the actual design on General Circuit Board by Soldering various components on the board and making required connections between the components.

- Various tests were conducted on the GCB before the actual flight.

- Developed the software for the GCB.

- The software was capable of Triggering the Recovery Mechanism based on pre-determined conditions using data from the Inertial Measurement Unit and Altitude Sensor.

- The software also recorded data from various sensors and in-flight events.

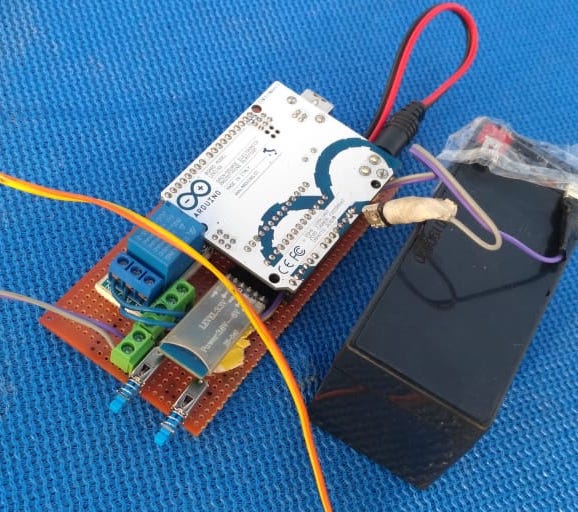

- Developed Rocket Launch Igniter including the hardware and software.

- The Igniter provided the ability to remotely trigger the launch sequence to light the Rocket Motor.

- The Igniter could be used with Bluetooth or Internet to trigger launch countdown and emergency abort of countdown in case of an anomaly.

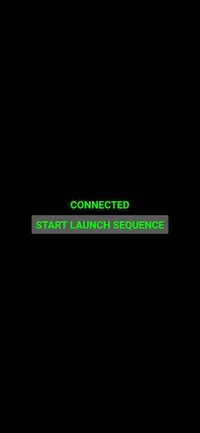

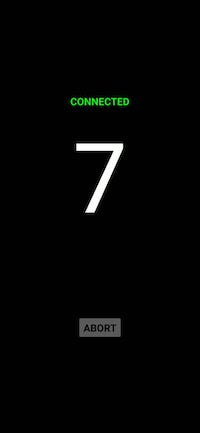

- Developed Android Application to communicate with the Rocket Launch Igniter.

- The application provided the ability to initiate the launch countdown and emergency abort the countdown in case of anomaly.

From left to right: Start Screen, Launch Pad Igniter interface, Bluetooth Selection Menu, Launch Sequence Starter interface, and Interface during launch sequence showing countdown and abort options.

- Developed Static Launch Test Pad to help Propulsion Team test different motors.

- Static Launch Pad used a load cell to measure the thrust and burn-time of the motor.

- The data recorded was used by Propulsion Team to analyse different fuel compositions for the rocket motor.

Testing of the rocket motor on the static launch pad. A load cell is used to characterize the thrust curve.

Project Accomplishments:

- 2 High Powered Model Rockets were successfully developed.

- A Remote Launch Igniter and a Static Test Pad was also developed.

- Many integrated tests were conducted of all the Systems:

- Numerous ground tests were conducted for the main Rocket Avionics Board and Wireless Igniter.

- 10+ Drop Tests were conducted for the main rocket avionics GCB.

- 9 Static Tests were conducted and data collected was analysed to determine the composition of fuel for the motor.

- 2 Rocket launches were conducted with all systems together.

Successful launch of our model rocket, demonstrating the culmination of our team's efforts in rocket design, propulsion, and avionics systems!